INTELLIGENT MAINTENANCE

Using intelligent maintenance tools rapidly decreases machine maintenance costs, eliminates the risk of downtimes and related loss of customers. Also, intelligent maintenance increases workplace safety and leads to significant savings in energy consumption.

- complete service process digitalisation

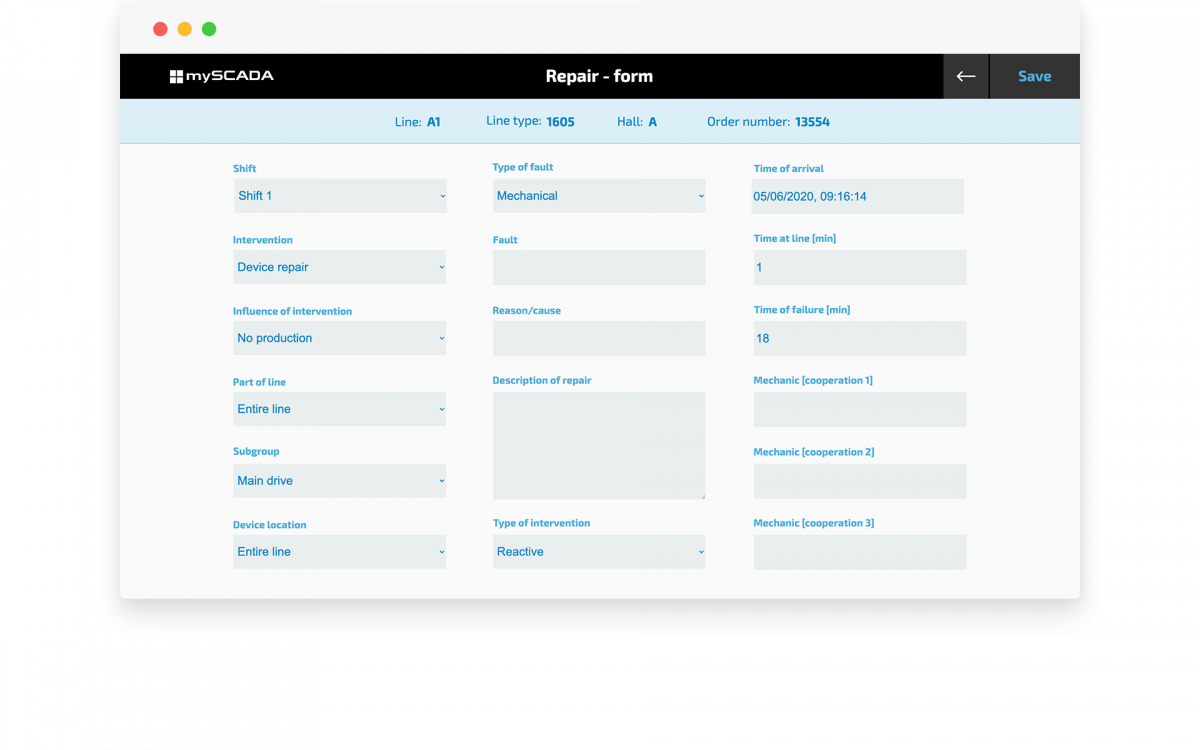

- switch from paper forms to electronic data entry

- detect typical service problems with complete history of service actions

- shorten the downtime of equipment by fast reaction

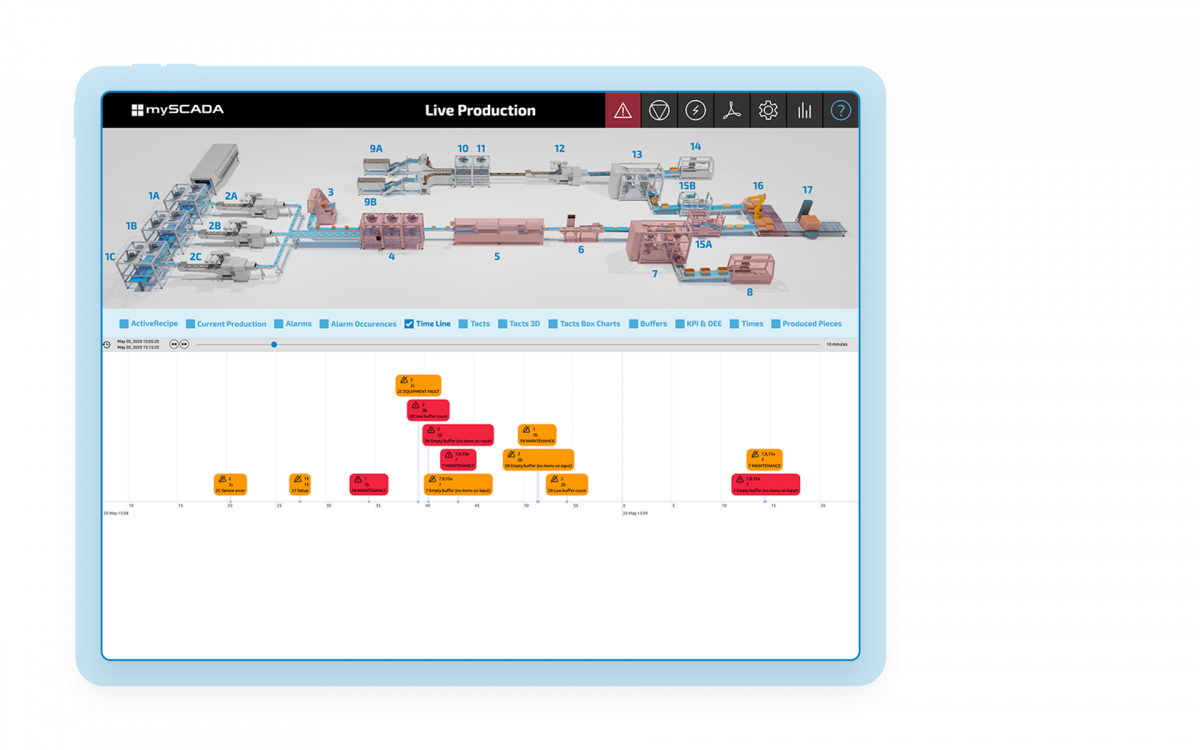

- automatically failure recognition and warnings

- SMS and email notification and escalation to relevant person

USE CASE

.

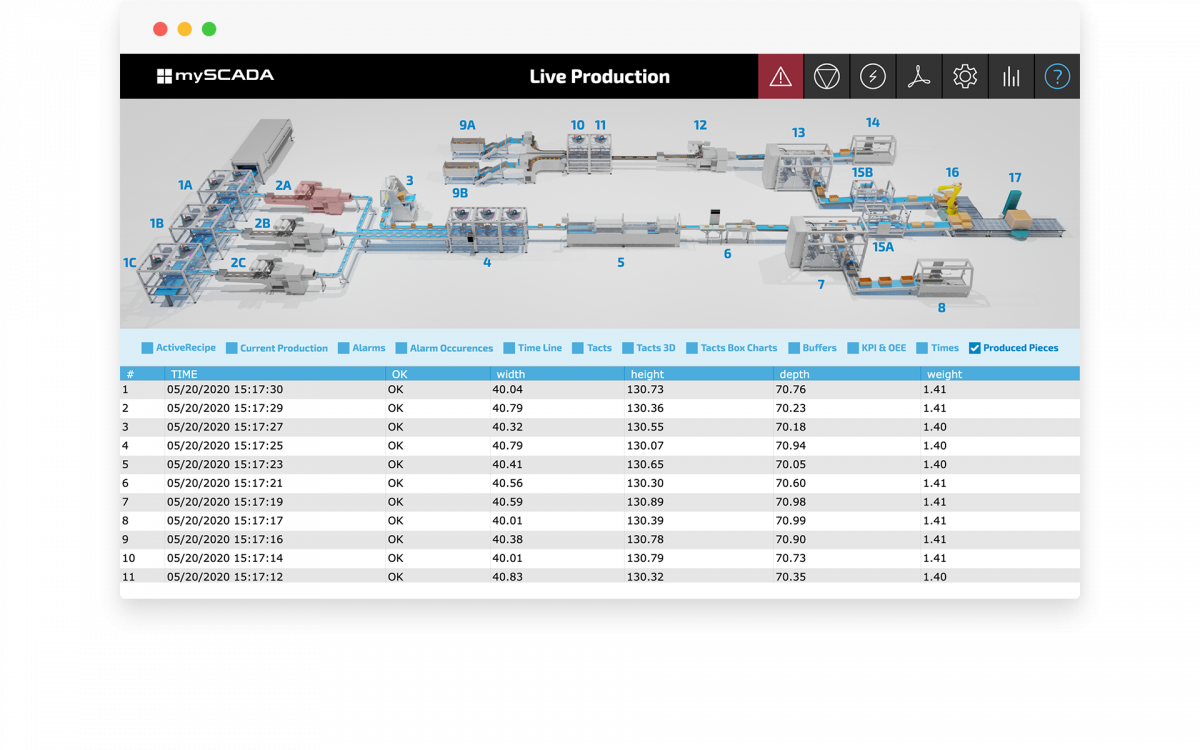

1. System finds out some problem in production process (real production end is not equal to the planned one).

2. System automatically calls service personnel.

.

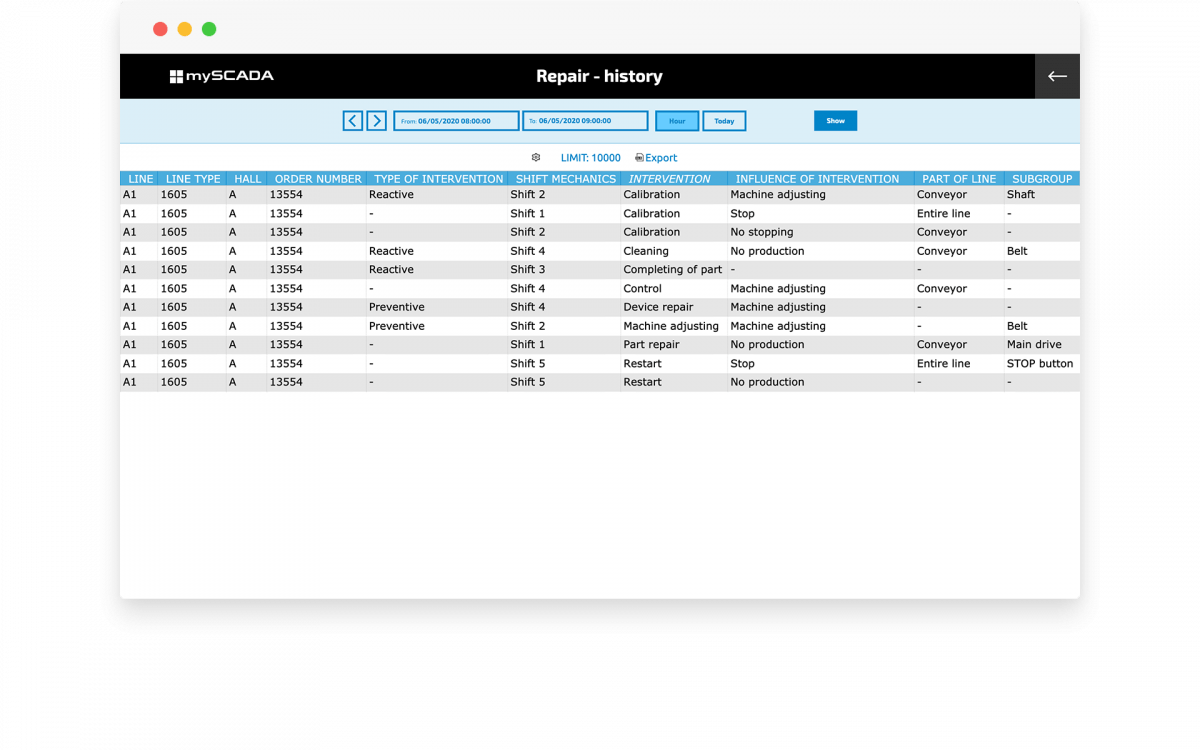

3. Personnel sees all data in the device (tablet).

4. Service personnel starts to repair, the form is automatically pre-filled (machine type, number of current order, …).

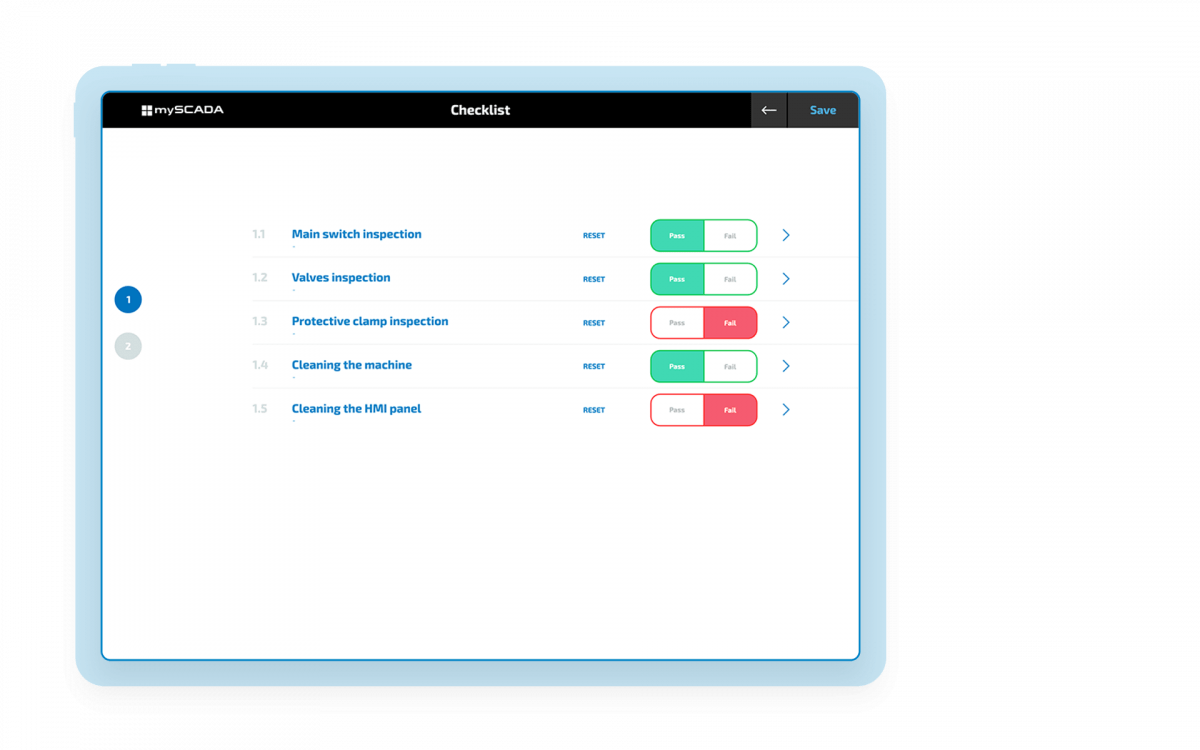

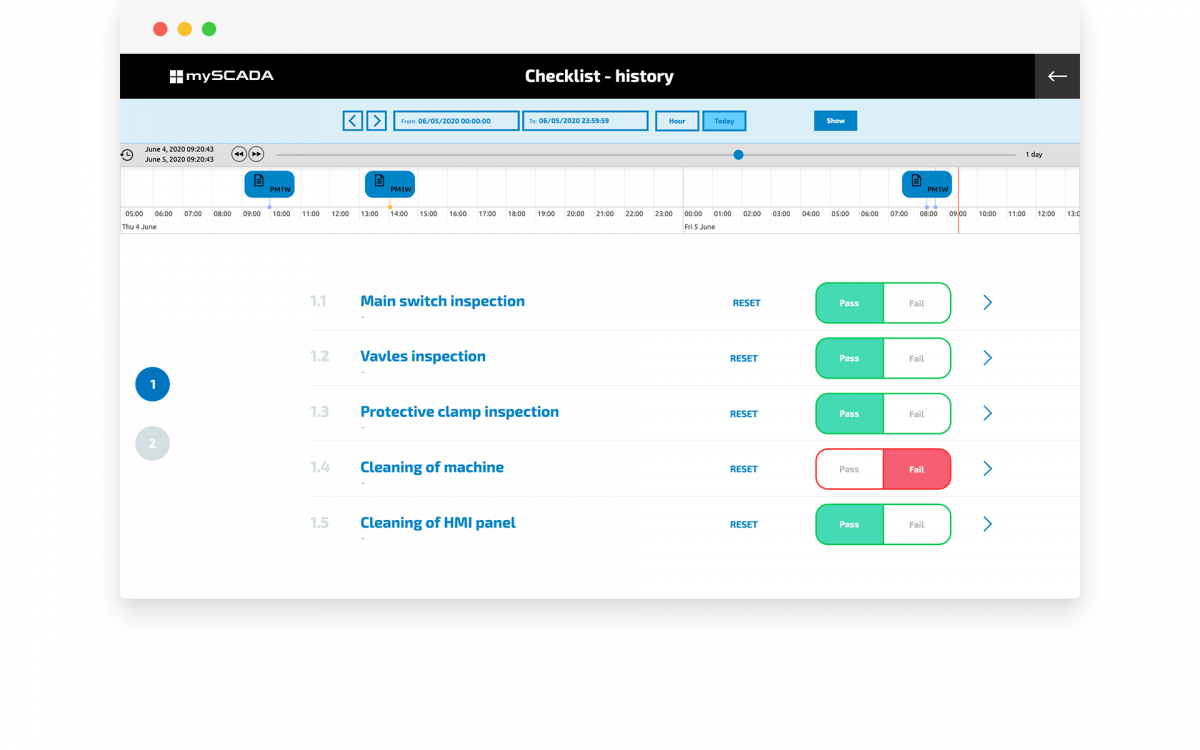

5. This checklist is used for regular revision of the machinery.

All forms (and changes) are logged for the shift leader.

Thanks to quick notification, the system recovery is fast and helps to shorten the costs and large time savings.

COMPETITIVE ADVANTAGES

.

overview of machine conditions

paperless forms and reports

prediction of machine wear (running hours)