myBOX – How It All Started

If it doesn’t exist, build it

About 15 years ago, we were knee-deep in wastewater treatment projects. Every installation meant building a full IT cabinet — Windows PC, switch, firewall, modem, cables everywhere… and hours (actually, days) of setup. And of course, when something went wrong, someone had to drive on-site to fix Windows, reconfigure the modem, or deal with whatever surprise the system decided to throw that day. Not exactly fun. So, we asked ourselves a simple question:

Why not make our lives easier?

After some research, coffee, and long evenings, we built the first myBOX — an all-in-one industrial device combining a SCADA server, firewall, 3G modem, and VPN client for remote access. We picked ARM architecture and Linux, which turned out to be the best decision ever:

- Linux gave us rock-solid stability

- ARM gave us low power consumption and wide temperature range

The result?

We ditched the bulky IT cabinet entirely.

Now, we could just put the myBOX right next to the PLC.

Installation time dropped from days to hours.

First myBOX installation on waste water treatment technology

And maintenance?

No more Windows updates.

No more “which version of software is this?” moments.

No more VPN setup headaches.

Everything was already inside one small box — plug it in, configure it once, and it just worked. For most users, it was as simple as mounting a PLC and forgetting about it.

Over time, we made it even better.

We added automatic backups to an SD card — if a box ever died, just pop the SD into a new one and you’re back online in 5 minutes.

We made secure remote connectivity setup a 2-click job. Even remote PLC programming became easy.

Of course, we had some funny moments along the way. One of our first customers called us in a panic: “myBOX is running slow!”

When we arrived, we quickly saw why — about 50 people were watching a live glass furnace process through their browsers, all streaming real-time data from the same box. The poor device wasn’t struggling; it was just trying to entertain an entire audience. :)

And the best part? It still held up — no crash, no freeze, just a few extra seconds of delay. Not bad for a device the size of a lunchbox.

A few months later, another customer went even further and decided to run an entire concrete production plant on one myBOX — batching, mixing, conveyors, remote access, everything. Amazingly, it worked! But that’s when we realized we might have made the hardware too capable for its own good.

That experience taught us an important lesson: even great things have limits — and it’s often our job to help customers design systems that make the most of myBOX’s power by using multiple units for larger applications.

Evolving with every generation

Since then, myBOX has grown stronger and smarter:

Generation 1: The pioneer — already had three Ethernet ports, GSM modem, SD backup, and wide temperature range.

Generation 2: We wanted more power, so we redesigned the casing to act as a heat radiator. High-performance CPU, still fully passive cooling.

Generation 3: Double the power again, a beefy heatsink, and features for the most demanding tasks. It’s a real powerhouse.

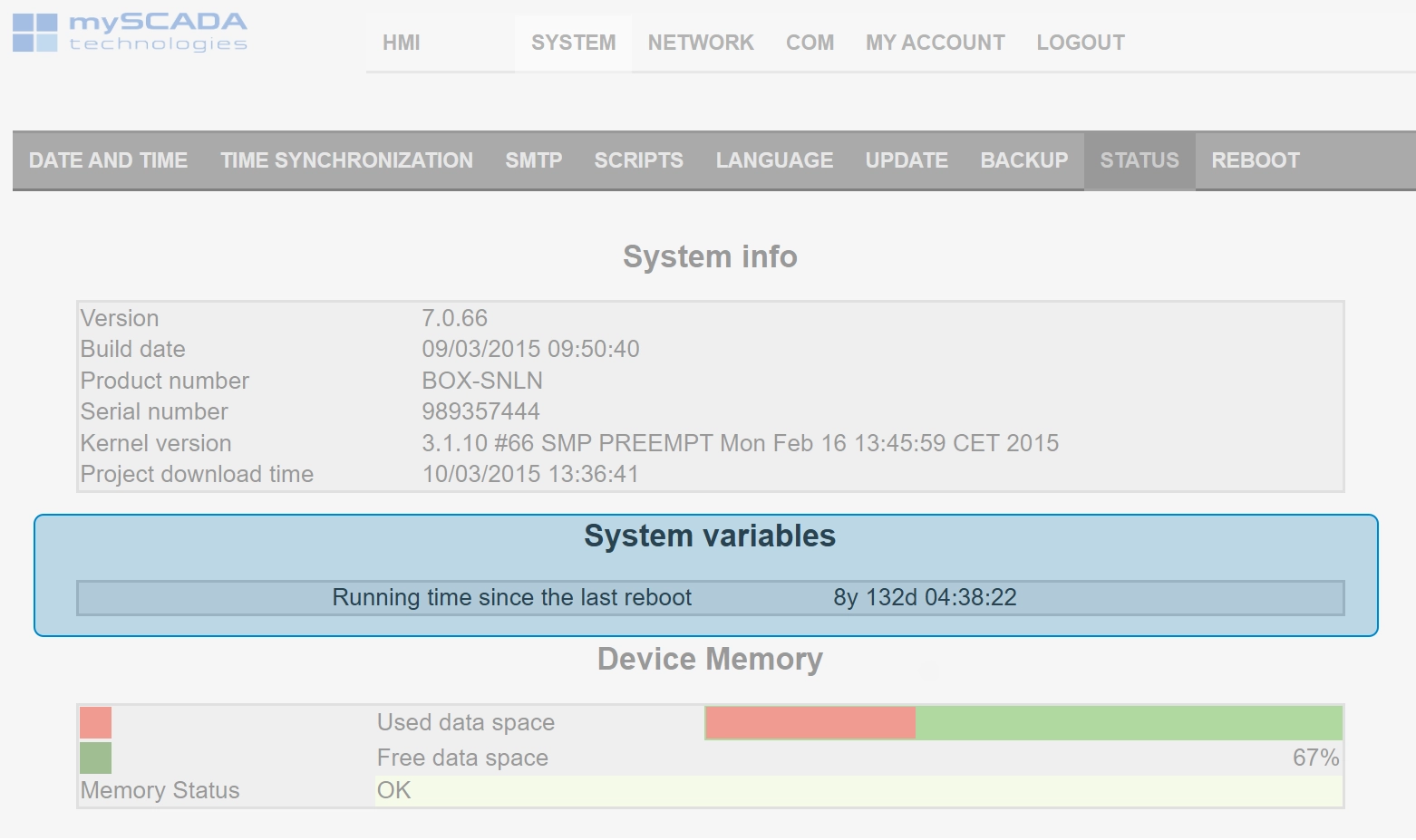

Today, myBOXes run in mines, factories, water plants, smart homes, power plants, and even boats – basically everywhere we didn’t expect it to go. It’s still small, reliable, and easy to set up — exactly how we wanted it to be. And honestly? We’re still proud of it. Because you probably won’t find another SCADA system that’s been running 8 years straight without a single interruption.

Curious?

If you’d like to see what myBOX looks like today (and what it can do), check out our latest models here: myBOX product page.

Whether you’re running a small plant or a full production line — myBOX might just make your life a lot easier too. 😉

We plan to release this third generation myBOX in December 2025 so stay tuned!