How mySCADA was born

A 25-year journey from factory floors to AI – This is the true story of mySCADA’s birth — told by its founder, Petr Svoboda

It all started more than 25 years ago.

Back then, we were an engineering company — an application partner of Rockwell Automation — doing large projects in all sorts of industries. We worked with Allen-Bradley PLCs and FactoryTalk View visualizations, designing big, complex systems that controlled everything from power plants to tunnels. We were good at it — but deep down, we felt things could be done better. Faster. Smarter. Simpler.

And that feeling was the seed that eventually grew into mySCADA.

The Early Days – Melting Shoes and Crystal Reports

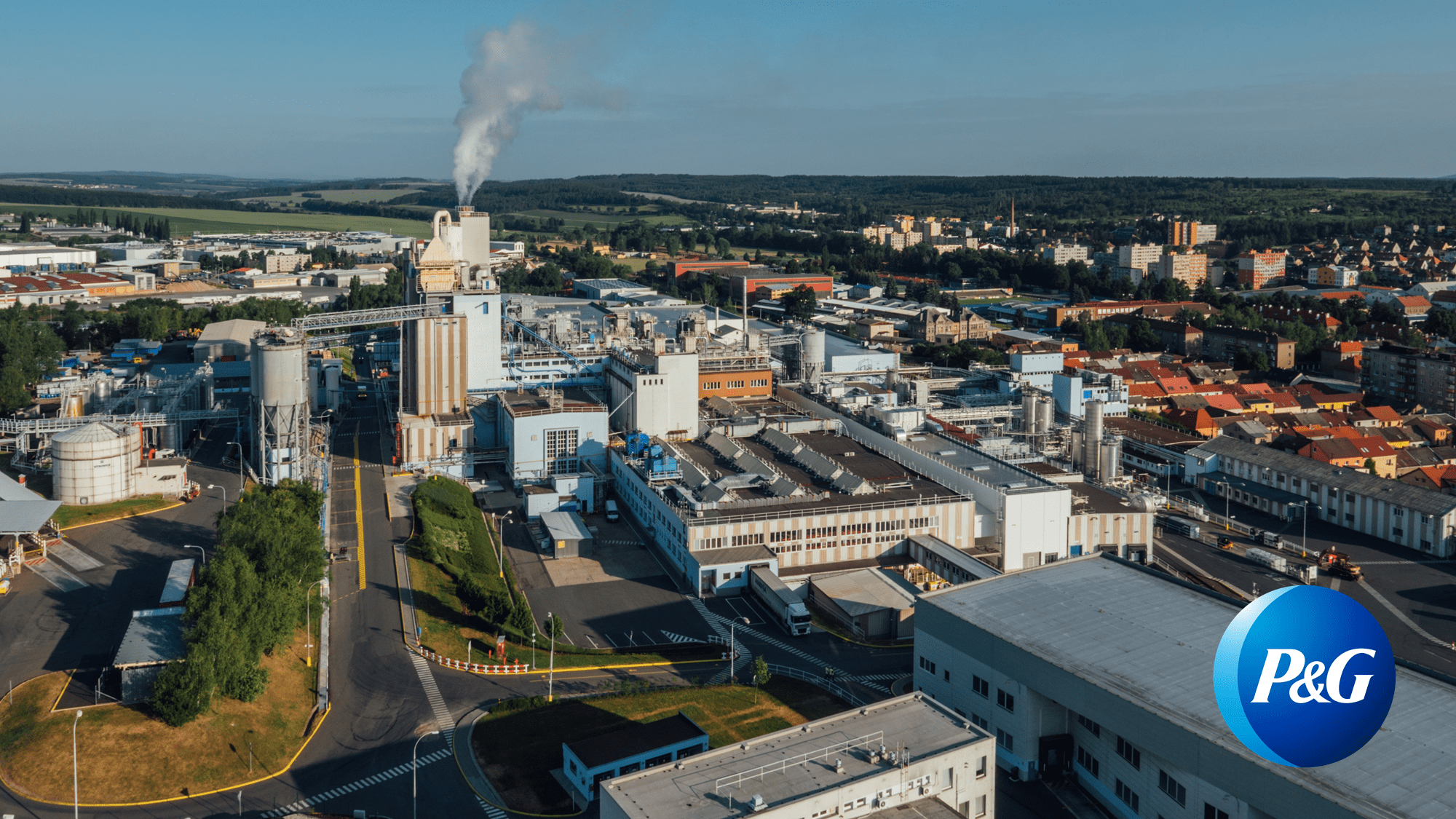

My own journey began at Procter & Gamble, working on detergent production. It was a fascinating mix of batch control, recipe management, and advanced visualization. But one thing kept driving us crazy: reporting.

We used CrystalReports, and the first report we ever ran took twenty minutes to compute. Twenty minutes! Eventually, by optimizing SQL databases, precomputing values, and squeezing every bit of performance from the system, we got that report down to under two minutes. A small miracle at the time.

And my first day at P&G? Let’s say it was… memorable.

During safety training they told us, “Always walk between the yellow lines.”

After a long day, I forgot that rule on my way to the car. When I reached it, I smelled something strange — melting plastic. I looked down — the soles of my shoes were gone! The floor was coated with chemicals that ate through them. Lesson learned: always follow safety procedures.

The Tunnel That Closed Itself

One of our most challenging and fun projects was Tunnel Control — a massive automation system for tunnels in Northern Bohemia. We were founding members of the national Telematics association, and our job was to design a fully redundant PLC system using Rockwell ControlLogix, connected over what was then the largest optical ControlNet network in the world.

It was a beast: visualization and control of 35 km of highway and tunnels, managing ventilation, EPS, EZS, fibrolaser, VMS signs… everything.

When the system was finally ready, the official delegation arrived to open the tunnels. As the motorcade passed through, the dust in the air triggered the fire detection system — and our system automatically closed the tunnel! Perfectly by the book, of course. Maybe too perfectly. Let’s say the delegation wasn’t expecting that much realism.

Power Plants, Fatigue Tests, and Finding the Limits

Then came the power plant projects.

Here, reliability was everything. We built fully redundant PLC and SCADA systems, and we had to pass EMC tests directly on the live installation. We passed all the control system tests — but failed the “72 days without a single SCADA failure” requirement. The commercial SCADA system just couldn’t handle the massive data load.

So we did what any engineers would do — we built our own historian and visualization layer on top of FactoryTalk View. After 30 sleepless hours before the FAT test, it worked flawlessly.

We passed.

And that feeling — of overcoming impossible technical limits through creativity and teamwork — stuck with us.

The Birth of mySCADA

After years of projects, one realization became clear: existing technologies were holding us back.

So we decided — “Let’s build our own SCADA.”

Something modern, web-based, secure, and lightweight enough to run anywhere — even embedded devices.

Our first implementation was revolutionary for its time: an HMI for iPads, written in Objective-C, using a local SQLite database and SVG graphics. Back then, no other company offered anything similar — for almost a decade. Customers loved it. Soon, we launched an Android version, and mySCADA Mobile was used around the world — from small machines to entire factories.

The natural next step was myPRO, our full SCADA system built entirely on open web standards: HTML5, JavaScript, and SVG. We made it work on both Linux and Windows, achieving reliability numbers that left other systems behind. And we were free — no more Windows updates breaking critical operations.

The Next Leap – AI and DataTalk

After 10 years with myPRO, we wanted to go further.

New technologies — cloud, AI, no-code — were transforming the world, and we didn’t want to follow. We wanted to lead.

That’s how DataTalk was born — what we like to call a post-SCADA system.

It combines everything good from traditional SCADA — redundancy, reliability, PLC connectivity, historian, and alarms — with modern IT trends: no-code development, AI assistants, time-series databases, and strict cybersecurity.

We thought it would take two years. It took four.

The result? See it yourself at www.data-talk.eu.

Although I am very fond of DataTalk and proud of it, mySCADA is the key system that has won my heart and remains one of our top priorities.

Looking Back – and Forward

When I look back at our journey, I’m incredibly proud.

We’ve achieved things only possible because of a fantastic team of passionate professionals who love what they do.

Sometimes people ask: How can a small company like ours compete with giants like Siemens or Rockwell Automation?

The answer is simple — we care.

We love our work, we listen to our customers, and we never stop learning — even if it means failing a few times along the way.

Long Story Short

- 15 years ago, you could control your factory from an iPad.

- 10 years ago, our Linux-based myPRO let you access your technology from any web browser.

- 5 years ago, myACCESS connected factories securely worldwide.

- Today, you can talk to your machines — literally — with AI Assistants in DataTalk.

- 5 years from now? Who knows. Maybe you’ll be the one guiding us to what’s next.

Ing. Petr Svoboda PhD.

CEO of mySCADA Technologies s.r.o.